What is a 2 pole motor?

A 2-pole motor is an electric motor design where the rotor has two magnetic poles – one north and one south. 2-pole motors generally run at high speeds because the synchronous speed (the speed at which the magnetic field rotates) is determined by the frequency of the AC power supply and the number of poles.

The stator (the stationary part) of a 2-pole motor has windings arranged to produce a rotating magnetic field with two distinct poles. While they operate at high speeds, the torque at these speeds might be lower compared to motors with more poles, which can operate at lower speeds with higher torque.

For a given power rating, a 2-pole motor is generally smaller in diameter compared to a motor with more poles because the stator length does not need to be as long to achieve the required magnetic field strength.

Due to their high speed, 2-pole motors are often used in applications where space is at a premium or where high-speed operation is beneficial. Examples include:

- Small fans

- Vacuum cleaners

- Power tools

- Some types of compressors

What is a 4 pole motor?

A 4-pole motor is an electric motor that has four magnetic poles. In an electric motor, the magnetic poles are points where the magnetic force is strongest. In a 4-pole motor, there are four of these points, creating a balanced magnetic field.

The rotating part of the motor. In a 4-pole motor, the rotor would have four sets of windings or magnets corresponding to the four poles. The stationary part of the motor. It also has four poles, but these are fixed in place. When current passes through the stator windings, it creates a magnetic field which interacts with the rotor.

When the motor is powered, the magnetic fields from the stator interact with those of the rotor, causing the rotor to rotate. Each electrical cycle in a 4-pole motor results in two complete mechanical rotations of the rotor, as each pole pair (north-south) represents one electrical cycle.

They offer a compromise between high-speed motors (like 2-pole) and slower, higher torque motors (like 6 or 8 pole). They also tend to be quieter and smoother in operation compared to motors with fewer poles because of the more distributed magnetic field.

4-pole motors are common due to their balance between speed and torque. They are used in applications where moderate speeds and good torque are needed, like in industrial machinery, fans, pumps, and conveyor systems.

2 Pole vs 4 Pole Motor

Number of Poles

- 2-Pole Motor: Has two magnetic poles, typically one north and one south. 4-Pole Motor: Has four magnetic poles (two north and two south).

Torque

- 2-Pole Motor: Generally, it provides less torque at lower speeds but can achieve higher speeds more easily. They are often used where high speed is needed. 4-Pole Motor: Provides more torque at lower speeds due to the slower synchronous speed, which makes them suitable for applications requiring more torque at startup or steady state.

Size and Design

- 2-pole motors are typically smaller for the same power output because they can spin faster, but they might need a gearbox for applications requiring lower speeds. 4-pole motors are larger for the same power because they operate at half the speed of a 2-pole, thus needing more magnetic material to produce the same amount of torque.

Applications:

- 2-Pole Motors: Often used in applications where speed is critical, like certain types of pumps, fans (when speed is more important than torque), and in systems where direct coupling to high-speed machinery is required. 4-Pole Motors: Used in applications where higher torque at lower speeds is needed, like conveyor systems, compressors, and machinery that doesn’t require very high speeds but needs reliable torque.

Efficiency and Heat Dissipation

- 4-pole motors might be more efficient at lower speeds due to less mechanical stress and heat generation from friction. However, this depends heavily on the design and application.

Cost

- Generally, 2-pole motors can be less expensive due to simpler construction for the same power rating, but this isn’t always the case as it depends on the specifics of the motor design for specialized applications.

Synchronous Speed

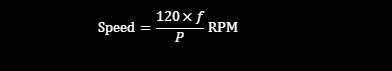

This is the speed at which the magnetic field (rotor speed for synchronous motors or stator field speed for induction motors) rotates.

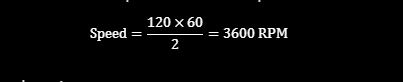

For a 2-pole motor, the synchronous speed in an AC system with frequency f (in Hz) is given by:

Where, P is the number of poles. Thus for a 2-pole motor at 60 Hz:

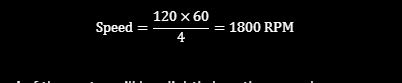

For a 4-pole motor:

Actual speed of the motor will be slightly less than synchronous speed due to slip in induction motors.